Pocket Door Anatomy & Glossary

Soffit- (SOPH-it)

In the hollow part of a wall, the linear (usually rectangular in cross section) enclosed area which, through stout framing members, provides support or attachment for pocket door tracks or pocket door rails/channels.

"The first sliding doors were usually carried on sheaves, or rollers,....This system, however has been displaced by the more modern sliding-door hanger, which suspends the door from the top. The carriers containing the rollers, or wheels, run on an overhead track placed in a recess formed for that purpose above the soffit of the doorway." (1889 Clarence Howard Blackall Builders' Hardware)

Jamb & header trim-

Very often the original installers applied the finish trim boards (whether stained or painted) leaving only 3/4 inch clearance. I guess they figured that was enough for the sheet metal riser straps to move back and forth when the doors were opened and closed. But partitions settle & decades later, when the track has to be accessed or when an enclosed channel needs to come down, the trim boards need to come off in order to do the job.

In this instance, the vertical trim (jamb trim) also had to removed. Please note-the wall casing (the edges of which are labeled here with capital letter C) does not usually need to be removed-it can stay attached to the plaster walls.

In this image, which has been bleached out to receive labeling, a line drawing from an old patent has been superimposed to illustrate the soffit (area where the running gear resides.)

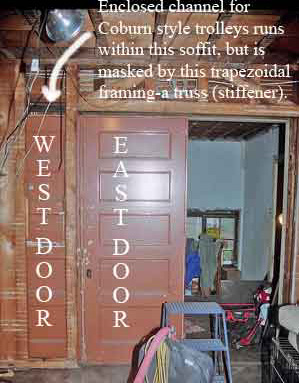

My "convention" treats pairs of door as "east" & "west". In this picture there is an added image of the "west" door-in its "open" position...inside the wall/pocket. The photo does not extend toward the "east door's pocket."

west door east door

This exposed wall illustrates the soffit area, although the truss framing masks most of the channel. However this photo also shows how, when you have a pair of doors, you can usually put one door in its appropriate pocket and then move the other door right next to its mate. (You might have to remove a barrier or center stop-located at the "50 yard line.") Having dislocated one door into "foreign territory", you will be able to detach an enclosed channel from the overhead track plate/carrying board.

(This photo does not show the removal of a channel).

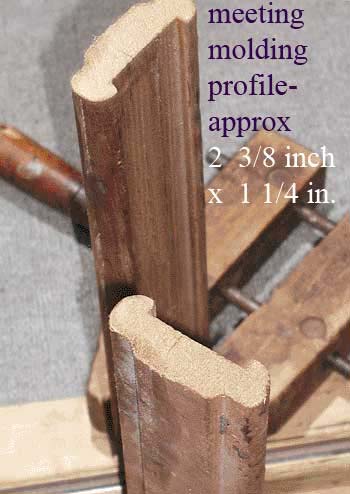

Parts of a door- Ninety five percent of pocket doors have a separate piece of decorative trim attached (with nails) to the leading edge. This is called the meeting molding. With pairs of doors, the meeting moldings nest-that is to say...the shape of one molding will be concave and the other will be convex. When the doors are properly aligned and the edges have nested or "docked together", you cannot see from one room to the other.

For purposes of repair, in the case of single doors (sometimes with pairs of doors), it is advantageous to remove the meeting molding. Why? You can thereby "shrink" the width of the door-sometimes gaining a whole inch!! (I think I mean losing a whole inch)-which will often allow you to move the door sideways and out! Here, the lock case has been removed and the meeting molding is coming off in preparation for setting aside the door.

This discussion of trailing edge and outrigger which I have been promising for some (long) time will appear in a new page I have created-"Regulating horizontal movement"

add an entry defining "track carrying board" and show the difference between an overhead track carrying board and a "side mounted track carrying board."

The meeting molding "grips" or encompasses the thickness of the leading edge. It's a molding! Moldings enhance, decorate and give a finished edge to architectural woodwork. But in this instance, an overlap occurs when the convex shape of meeting molding merges with the concave shape of the second door in a pair (or when a single door comes to rest against the destination jamb.

Both the unfinished edge of the door and the meeting molding are mortised to receive the edge pull or pocket door lock.

In pocket doors... ratios, proportion and clearance are everything!! When taking down an overhead enclosed channel to raise up the track board, it is imperative that the door be set aside. But if you are dealing with a pair of doors, you can dislocate both doors to one side of the opening. See the photo above with the brown painted doors.

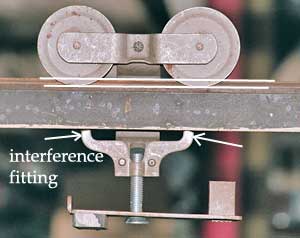

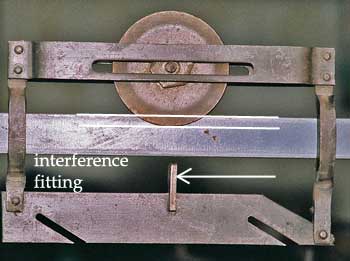

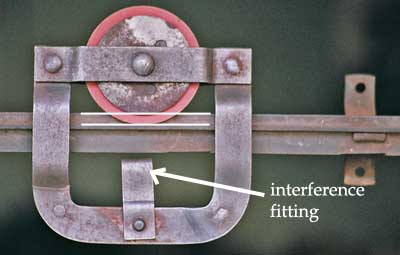

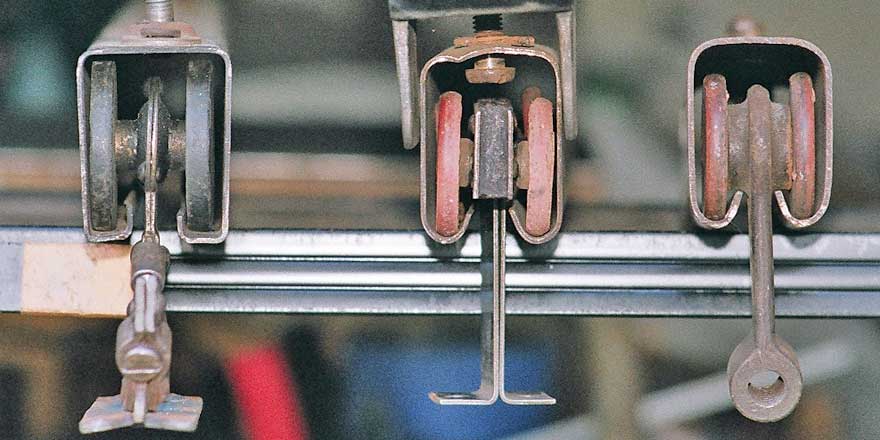

Interference fittings-Manufacturers foresaw the need to keep their products from derailing. Time for an editorial note...Whenever I look at online discussion forums-there is always a lot of talk (and opinion) about malfunctioning pocket doors. Invariably somebody will try to be helpful by saying, "Your door is probably off the track. Lift it up and try to put it back on the track." Take a look at three very different pocket door hangers. Each hanger was outfitted by the manufacturer with an interference fitting.

Look at my annotations. A little reasoning will convince you that if the wheel assembly were to be lifted off (this happens if the door is dramatically jostled), then instantaneously the interference fitting rises up against the bottom of the track to prevent derailing. Is this not so?

Furthermore, I want to say...on the day of installation...these hangers were slid onto the end of the track. They didn't come off...unless someone who couldn't take the time to understand the concept thwarted the intentions of the inventor by bending the fitting, by "trimming" the height or by outright removal.

The "Dix" hanger, shown at right, is actually an exception to what I write above. I will make a page about the secret feature which allows a Dix hanger to be removed/installed in the middle of the length of the track.

Red fibre-What is it? I don't know, but here is an extract from an old commercial catalog. If red, gray and black fibre was available for sale to craftsmen and tradesmen, I am confident that manufacturing concerns could most certainly obtain this material in whatever shapes they needed, (sic) wheels. After 4" cast iron wheels "passed from the scene", rollers made from discs of hard fibre were commonplace. Also, steel wheels often received an inner core of fibre for noise reduction. Look at this photo-the left hanger has two metal discs with a inner "concave tire" of fibre. The design of the right hanger "is the opposite"- it has a big grooved disc of fibre flanked by two smaller metal discs.

Black and red fibre wheels in enclosed channels-

The black wheels always seem to be flat edged and 2 1/8 inch diameter.