This was the third job I received from my brand new one page website-launched in late Fall of 2009. After the initial inspection, I knew 1) there was almost no room for the doors to move, 2) the doors had been converted from a bottom sheave installation to a top hung Coburn channel and 3) I had been hired to fix them-because that's what it said on the webpage!!

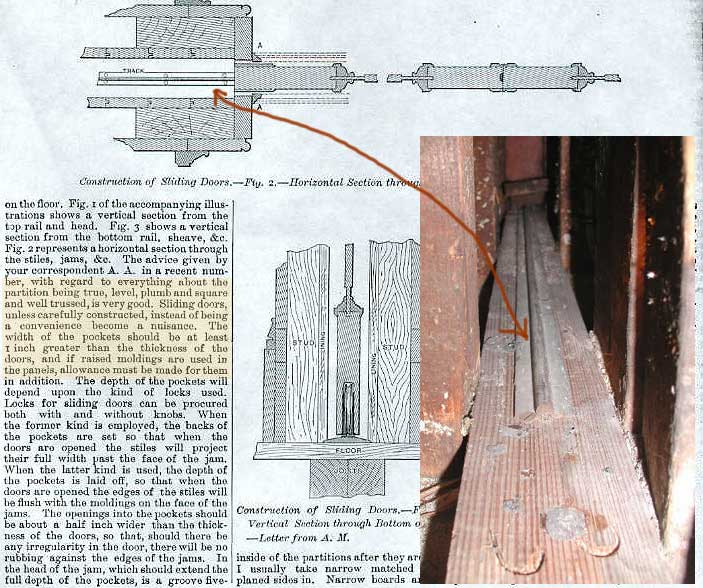

Do you see the bruised moldings in the above two photos? They are bolection moldings-which is fancy talk for "they stick out from the surface of the door". Look at the text in the old journal directly to the left and see the contributor calls them "raised moldings."

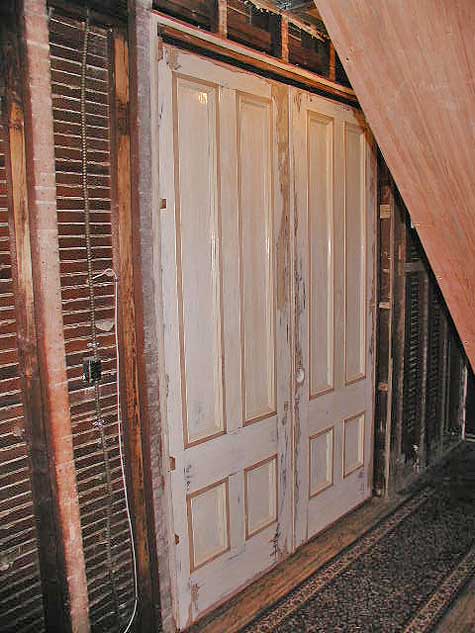

My new clients were serious renovators who had stumbled upon hidden pocket doors. The original installation had provided no "wiggle room" to begin with and over the decades the studs had bowed. The overhead soffit, as well as the floor track, also might have somehow shifted. Some brave soul had tried to circumvent the difficulty by switching the doors to a top hung enclosed channel.

I eventually realized the doors were not only pinched sideways, but that there was insufficient vertical clearance. If you will think hard and look elsewhere on this website, you will understand that a top hung enclosed channel requires a certain amount of "headroom". Maybe the second generation installer (the brave soul) did cut the door bottoms or maybe not. But the doors were heavy and at some time after the overhead track board was nailed in place (that's what they did-only used nails), the weight of the door began to pull down the track carrying board.

Epic Repairs #2-Hemmed in on all sides (and top to bottom too!) A job I would not have able to accomplish had not the owners already taken off lath and plaster.

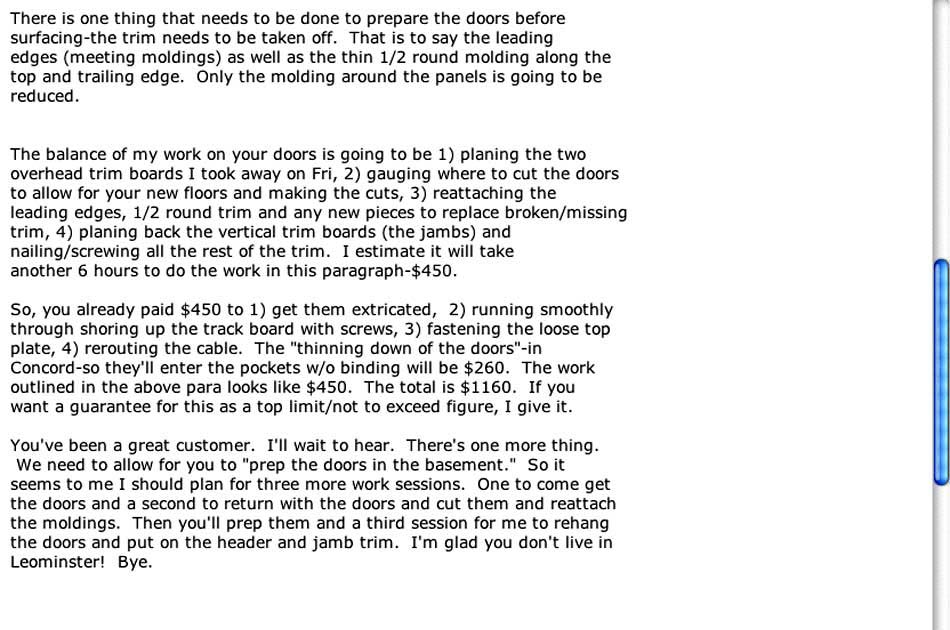

Doors back home after the bolection moldings were sanded offsite; wood trim and wheel assemblies in the process of being reattached by me; every surface of the doors were "scuff sanded" by the owners in preparation for eventual painting... [walls ready for sheetrock, also!]

I began my repairs at the top- 1) shoring up the track carrying board, 2) working with the track adjustment screws and 3) making sure the trolley wheel assemblies were tuned up.

It became apparent that I was going to have to cut the door bottoms to gain clearance. Moreover, the homeowners had boxes of flooring stacked up in the hallway-they were planning on adding a new layer of wood flooring!!

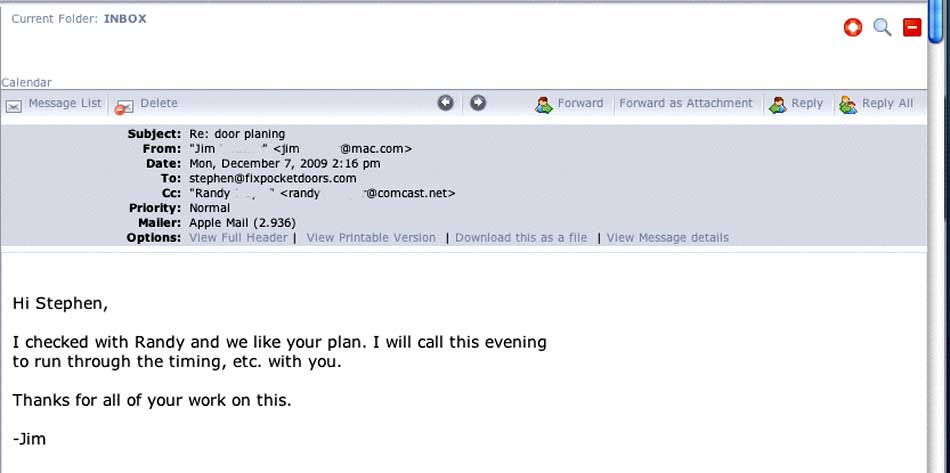

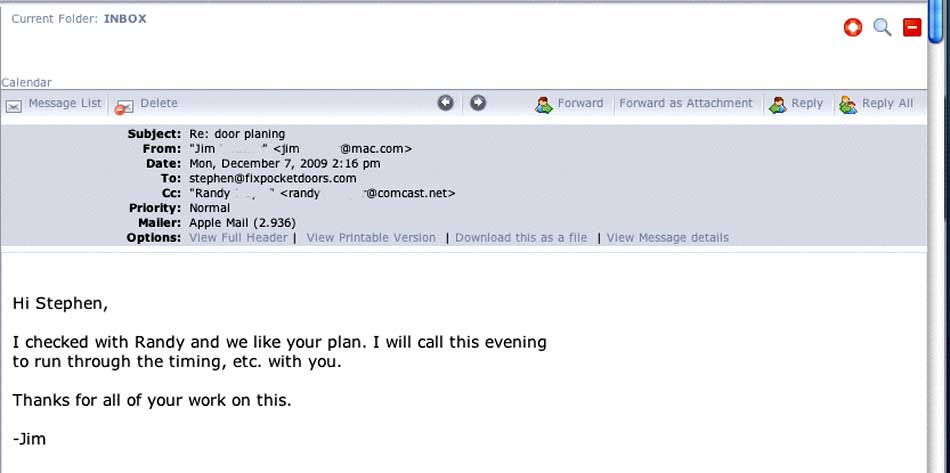

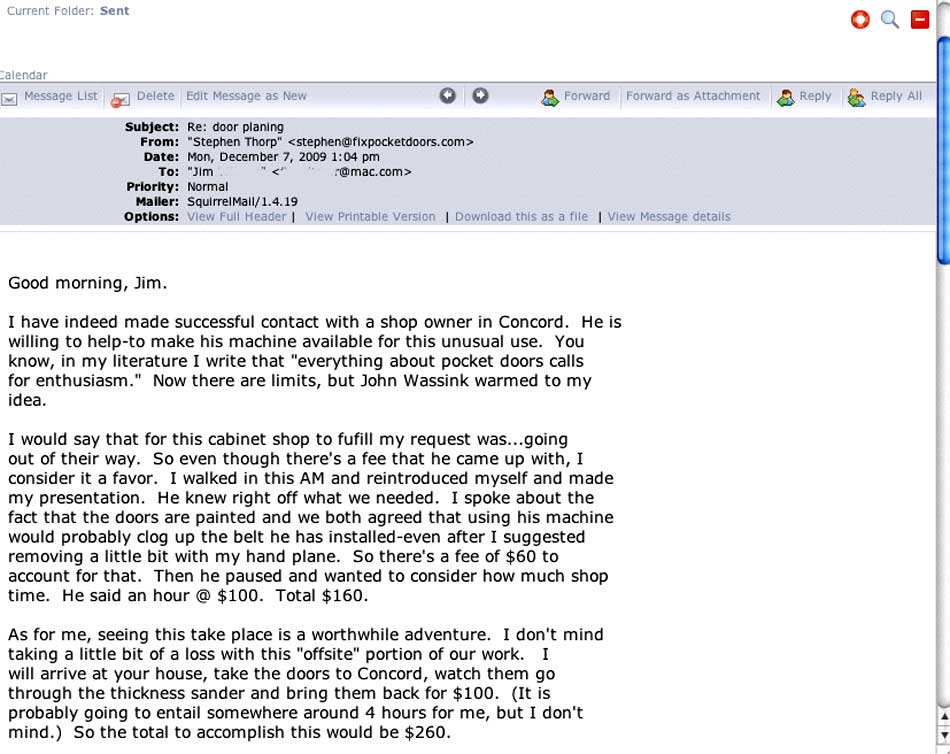

These door needed oxygen-lots of oxygen! I counseled against any attempt to remove wood from the bowed studs because that would weaker them even further-possibly starting a new episode of warpage. I told Jim that the solution was to shave off some of the bolection molding. It would have been sheer folly to laboriously plane by hand. Any attempt to use a belt sander would have ended in a craftsman's nightmare.

Then I remembered a cabinet shop in Concord, MA where they had an expensive wide surfacing machine that used a sanding belt.