Or maybe Field Guide to Pocket Door Systems or Guide to Pocket Door Kinetics? One thing is for sure. This is NOT a guide to pocket doors-because there is no such thing as a pocket door! Huh?

Inventors who were competing to patent ways of conveying doors from within the confines of hollow walls made grandiose claims. They typically stated they were making improvements but they were not improving doors! And the companies to whom they assigned their inventions were not making doors!

Your vanishing doors or sliding doors were made locally-not shipped across the country from some "pocket door factory." That is why I say there is no such thing as a pocket door per se. The architect or builder specified dimensions for every door opening. If they wanted the door to swing, they specified hinges and locksets. If they wanted the door to move sideways, thereby closing an opening, they ordered pocket door locks & hardware and specified pocket door hangers and track from a company such as Lane Bros., Richards-Wilcox, Coburn, Prindle or Warner.

The doors came from local suppliers-and only became "pocket doors" when they were outfitted with pocket door top plates, hangers and hardware. That is the end of my semantic exercise. Now, the information set forth below is a compilation of my own observations mingled with extracts from authors from the turn of the century...the other century!

Illustrated Field Guide to Pocket

Door Mechanisms

Click this thumbnail to see a full sized image of Dix hangers languishing away-on top of doors for sale at New England Demolition & Salvage, New Bedford, MA.

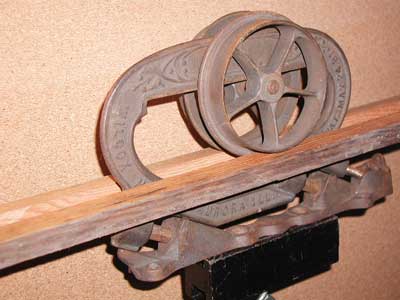

We are dealing with a 50 year period-approx 1875-1925. Although parlor doors using trackless mechanisms and parlor doors with bottom sheaves (wheels/rollers) were the earliest competing technologies, by early 1880s, a third construction appeared. Inventions for overhead tracks, door hangers and top door plates sprouted from all quarters. Here is a "studio mock-up" showing parallel wooden tracks-an arrangement which allowed quiet operation of the doors.

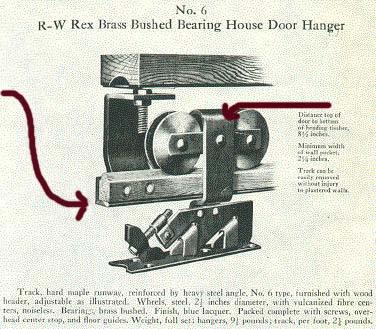

Wanna get confused? Stay tuned! Here are the specifications for the Richards-Wilcox "Rex" Door Hanger. "Track, hard maple runway, reinforced by heavy steel angle, No. 6 type, furnished with wood header, adjustable as illustrated. Wheels, steel, 2 1/2 inches diameter, with vulcanized fibre centers, noiseless."

This hanger has a 45 degree angle adjustment screw. And the riser strap arches above and over the wheels.

Dix hangers are like today's inline skates. The track is a sandwich of two metal bars flanking a bullnose edged wooden rail. Their steel wheels (2 5/16" diameter) are also a sandwich-metal discs with a core of rigid red fibre. The fibre disc is concave and conforms to the wooden convex rail. The combination renders the mechanism substantially noiseless. Notice-does not have a 45 degree angle adjustment screw.

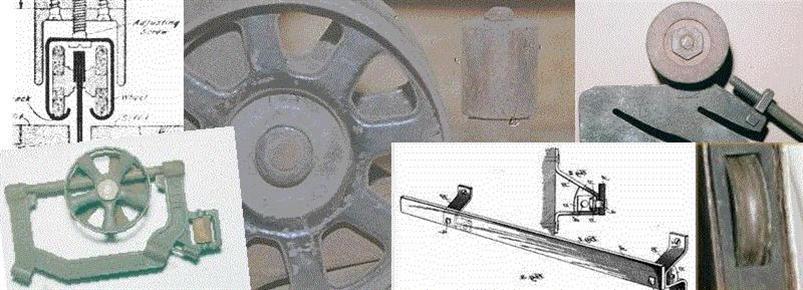

STEEL WHEELS FOR MONORAIL TYPE TRACKS

Notice in these illustrations, the same basic wheel style with four different track configurations-and there are more!

These seemingly identical cast iron hangers are of a different scale. Observe the breadth of the metal at the arrows.

Before the invention of ball bearings, the name of the game was "anti-friction." Large wheels (3" or 4" dia") provided smooth operation over parallel hardwood tracks. If you ever get the chance to move a pocket door with these big wheels you will be astonished at the almost effortless motion.

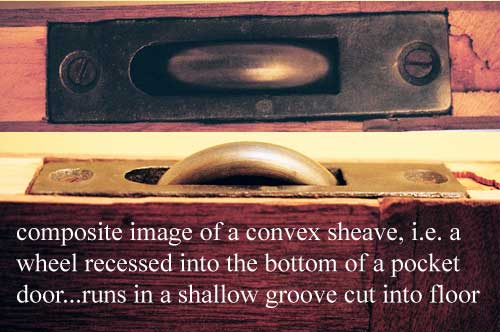

The first sliding doors were usually carried on sheaves, or rollers, located at the bottom of a door, these rollers traveling on a metal track, which was either inserted in the floor or placed on its surface. This system, however has been displaced by the more modern sliding-door hanger, which suspends the door from the top. The carriers containing the rollers, or wheels, run on an overhead track placed in a recess formed for that purpose above the soffit of the doorway. (1889 Clarence Howard Blackall)

To the left is a "vestigial" floor track found in a pre-1890 home. The thickness of the half round track is less than a "little finger." Overall width from flange to flange is 1 3/16" and height is 3/8". Length per cast iron section is 23.5" Bill Rigby tells me this track was also made in brass.

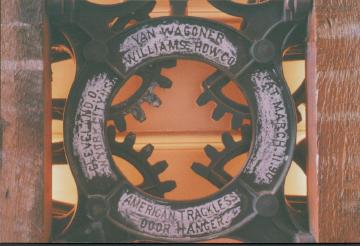

Trackless Pocket Door Systems (panel below)

In the gentleman's photos I saw two different types of sheet metal hangers. So I "posed" these two samples I had and sent him this photo.

The machine screws are quite different. On the left is an ordinary thread size-18 TPI (threads per inch)-which was standardized long ago and, being still available, is usually referred to as "common hardware." The threads pass through a rectangular nut which was anchored to the slotted hanger. (The slotted hanger on the left is a relic missing its wheels).

The screw on the right is 30 TPI (threads per inch). And the screw enters into a rather light duty, folded piece of sheet metal (a loop) which 1) is internally threaded and 2) is riveted to the "nose" of the slotted metal hanger. When I say "light duty" I do not mean to imply in any way that it is inadequate.

So...the point of all this is that...some door hangers (for 2 1/8 inch diameter wheels require machine screws which are 30 TPI. I make them to order. And I also make top door plates for these hangers.

TROLLEY-TRACKS FOR SLIDING DOORS

but a better name would be

ENCLOSED CHANNELS FOR SLIDING DOORS

Coburn style channel is ubiquitous in the Massachusetts Bay area. The trolley wheels consist of 2 fibre discs connected by a steel axle. The wheels are 1 7/8 inch diameter. Two axles are put under a yoke.

The yoke receives a pair of riser straps coming from the door plate. These are capable of supporting a 7' wide pocket door!! I have worked on such a door-and there was no problem with the trolleys. See "recent repair" for a discussion of the most common problem which I encounter.

"Dix Mfg Co, Balto MD" is the legend on the wooden header in this color photo. I found fragments of another rubber stamping saying "Williams-Burditt, Boston, MA" (This firm must have been local distributors for Dix Mfg).

I received an inquiry from a homeowner on the South Shore (of Massachusetts Bay). He had visited Olde Bostonian (Architectural Antiques & Custom Woodworking) in the Dorchester neighborhood of Boston http://www.oldbostonian.com and they gave him my humble flyer. I asked him to followup with photos if possible. As I looked at his photos I noticed something peculiar. And I responded with a hasty "studio" photo of my own-with annotations.

Here is yet a third variation! The catalog depicts a flat wooden track, reinforced with metal. And the track is fastened to the pocket wall!

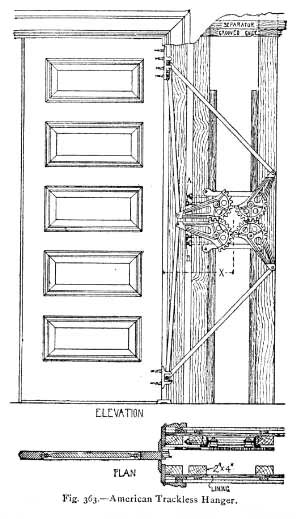

Mr. Blackall's information is fine/was fine-in part. But he didn't mention that some pocket doors don't have wheels! In 1881 there is a patent depicting a mechanical assemblage of articulated arms; that is to say, flat metal bars riveted together as in scissors. These assemblies were made by blacksmiths and the technique was called "hammer welding." There was not gas welding; there was not arc welding. It was horse and buggy times.

The inventor, Edwin Prescott, used terms like moveable fulcrums, radius bars and counterbalances. His system was highly regarded and, as it turns out, is capable of keeping a door suspended indefinitely-for decades.

I have repaired a very wide single pocket door outfitted with this mechanism patented by Edwin Prescott. My report on this remarkable "non-repair" is on my page called Epic Repairs #1

The left drawing show a Prescott door hanger suited for light duty. That is to say...sized to support one 36" door. The right drawing shows a "trussed" version which can support a 4 foot or 5 foot single door.

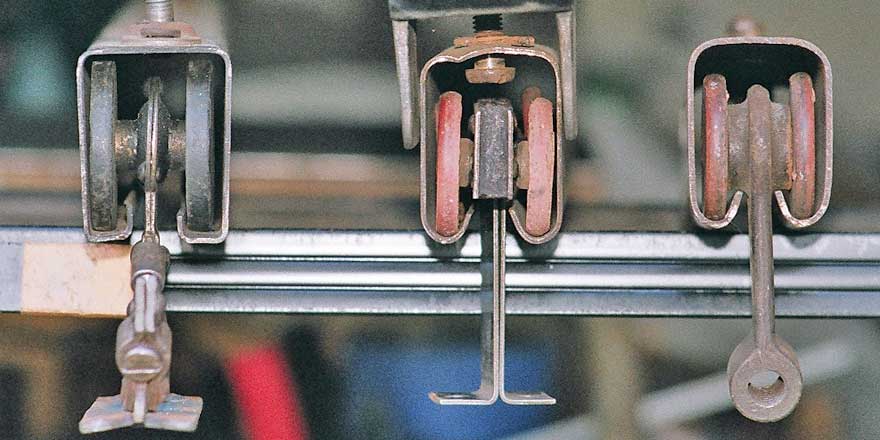

Above left-a "square-bottom" enclosed channel for 2 1/8 inch diameter fibre wheels which are black. Notice: this hanger has ball bearings-they are inside the "stamped" or "formed" sheet metal axle housing. This sheet metal axle housing is comprised of two sections riveted together. Also, there is a 45 degree angle adjustment screw which raises/lowers the door. In addition...the track is also adjustable with regard to the track carrying board...or maybe I should say the channel is adjustable with regard to the "channel carrying board."

Above in the center-a Coburn channel with red fibre wheels 1 7/8 inch diameter. There isn't any 45 degree angle adjustment screw, but you can adjust the channel for height via machine screw (you have to look closely with good light to see the heads of the machine screws). Hanging down are symmetrical riser straps (of sheet metal) which are screwed to the door top (along with a sheet metal door plate-not shown here, but shown in other photos higher up on this page.)

Above on the right-a Coburn channel containing a cast iron Ballard hanger. Ballard wheel assemblies, while distinct from Coburn wheel assemblies, used the Coburn channel (no such thing as a Ballard channel). Note: The Ballard hanger has ball bearings-so I would say it was made after Coburn's sheet metal hangers (shown in the middle). On the lowest part of the Ballard hanger you can see a "hollow" loop-it's not a hollow loop...it's a threaded hole-on an angle-for an adjustment screw.

Above...notice in the line drawing...the door hangers have 45 degree adjustment screws. These hangers attach to the door top via typical Lane Co. "architecture", but the whole assembly is lightweight compared to the massive Lane Co. anti-friction wheel assemblies of 1890. We differentiate these because they are Lane Co. trolleys in a channel, not Lane Co. parlor door hangers riding on a side mounted "bar-on-edge" track. (Postscript-I have not seen these yet)

HERE ARE SOME UNSORTED, UNCATEGORIZED IMAGES

Lane New Model parlor door hanger

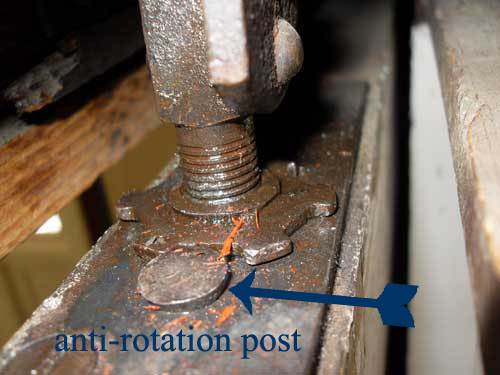

This anti-rotation post, which I first encountered on my September 2010 repairs in Atlanta, taught me even more patience than I already had-or thought I had. It must rise up to allow the "cogged" wheel to turn. The post was rusted; repeated applications of penetrating oil (spanning two workdays) finally freed the mechanism.

COMPARISON OF DIFFERING ENCLOSED CHANNELS

Composite photo on right (with rubber stamp) shows a WILCOX channel (before merger w/ Richards). See caption below for other channels and their wheel assemblies.

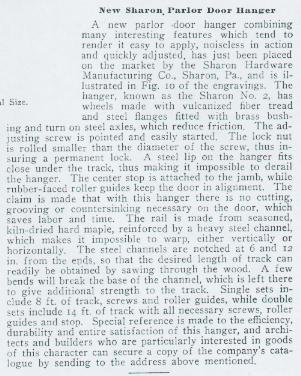

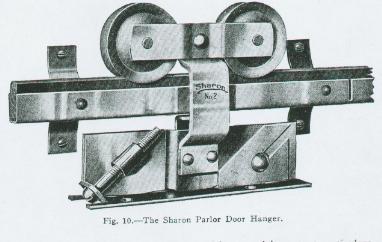

The Sharon parlor door hanger should remind you of the Dix hangers higher up on this page. However...There are important differences.

The track is comprised of a U-shaped metal member and is lined with a wooden insert which projects above the metal. The track is side mounted-not top hung. The wood on which the wheels roll is flat-not domed like the Dix track. Take the time to read the press release. For ease/rapidity of installation in the field, the wooden component of the track was meant to be sawn through. Then the installer was instructed to snap the track to the desired length. Ques: How could the original installer "snap" the track if part of the track was metal? Ans: The factory made strategic partial cuts in the metal 6" and 12" from each end. Look in the engraving-towards the right. Quite bold...don't you think!

Sharon hanger off Ebay

The owner of this Boston "South End" townhouse had empty pockets! He obtained totally suitable doors from a nearby demolition site, had them refinished by Olde Bostonian Architectural Salvage and had the doors delivered (and placed on his dining room floor). Then he looked around for someone who could work on pocket doors! How's that for a faith-based initiative!? <:d)

I'll make a page on this scrumptious repair, but for now note the metal plate "let into" the floor. It's an old strike plate for a French door flush bolt. When people cannot repair pocket doors, contractors frequently suggest mounting them...or substituting other doors...as French doors.

This is a "toasted pocket door." A big toasted pocket door. Somewhere in my files I have a scan from an old book-a text extract from an architect or an engineer-which clearly states the need for adequate "blocking" to be installed in all buildings. Carpenters are supposed to install firestops to slow the spread of fire. This toasted door is a testament to what happens in a wood framed residence when the fierce heat from a fire funnels through a gap in the framing.

This five foot wide single door and a nearby pair of doors were scorched by a basement fire. They survived but their days as varnished doors were over. The house survived the fire rather well, but the wall surfaces were gutted and a fire restoration contractor had to deal with the smoke damage. The builder had sprayed many areas with a white shellac product.

More to come when time permits.

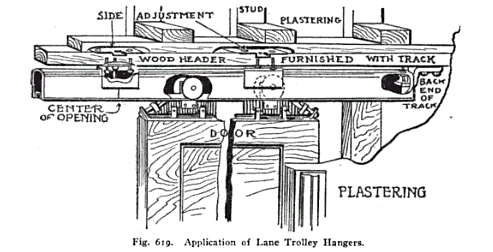

Another very satisfactory arrangement for hanging sliding doors is a trolley-track similar to that shown in Fig 614. The trolleys or wheels which carry the door run inside of the track as shown in Fig. 615. As the track is made of rolled steel it possesses a great deal of strength, and therefore it requires but a few supports and can readily be adjusted. It is absolutely impossible for the wheels to get out of place on this track or for any dirt to get inside of it. It also requires less space between the studs than other tracks, 3 inches being sufficient for doors 1 3/4 thick. Several grades and kinds of hangers are made to suit different requirements. (Building Construction, published approx 1910)